Ailsa Watt

Mechanical Engineering Student

PORTFOLIO

A Little

About Me

I am an incoming senior Mechanical Engineering student at the University of California, Irvine. My hobbies include hanging out with my friends, going outdoors, and supporting my club, American Society of Mechanical Engineers @UCI. I am also a physics tutor at UCI and a ropes course instructor at various theme parks on the side!

02

Table of Contents

01

Vehicle Engineering Internship

02

Spacecraft Thermal Management System

03

Mechanical Engineering Internship

04

Attack on Droid Anthill

05

SolidWorks Rollercoaster

An analysis and presentation of my accomplishments from the last couple of years.

06

Gateway to Blue Skies

08

Solar Oven

09

Stage Extension

Vehicle Engineering Intern - Northrop Grumman

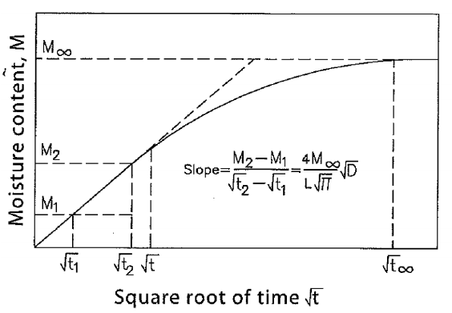

At Northrop Grumman, my project was to design and test materials to prove hygrothermal degradation. To start, I began with developing and understanding Fickian models of diffusion, with which demonstrated diffusivity increase and shortened fatigue life. Then, I helped design the experiment in which we would test 360+ specimen by moisture conditioning them, then subjecting them to shear and tensile stress. I also conducted microscopy examination of conditioned specimen and developed an understanding of microcracks. The effect of this experiment is to alter company-wide testing procedures to account for hygrothermal cycling degradation.

Spacecraft Thermal Management Systems - UCI

The Spacecraft Thermal Management Systems (STMS) project presents a research endeavor led by students aimed at devising a Variable Emission Device (VED) tailored for satellite applications. In the vast expanse of outer space, spacecraft encounter substantial thermal fluctuations owing to the absence of Earth's atmospheric protection. The primary objective of this project is to address this challenge by developing a VED utilizing thermochromic materials. These materials enable the device to adjust its emissivity in response to environmental

conditions, thereby facilitating effective temperature regulation for spacecraft.

The goal of the High Heat Flux Team is to experiment

with the current set up using different cooling methods for faster, more efficient cooling. We use a cylindrical heating chamber with a copper rod inside, connected to thermocouples to measure the temperature. Inside the heating chamber, we use a metal heating cartridge and outside the chamber we use an impinging jet to respectively heat and cool the heating chamber.

You can view my End of Quarter Report here: https://drive.google.com/drive/folders/1QBfHC5kxAwvwAxVzcKj40j_FAyxUxE29

REACH Database - Ducommun

My project was to make the onboarding and training for the calculation of the Registration, Evaluation, Authorization and restriction of Chemicals (REACH) laws and requirements related to Ducommun part materials to be easier and more efficient. I started by calculating individual mass percentages of materials by hand and imputing into the REACH database.

I created an Excel sheet and Quick Start Guide to save time and money in REACH calculations. Saved Ducommun $16,000 in work time, and $250,000 in cost avoidance. I categorized and sorted complex parts, articles, substances, and raw materials and calculated mass percentage of elements and compounds within Ducommun parts.

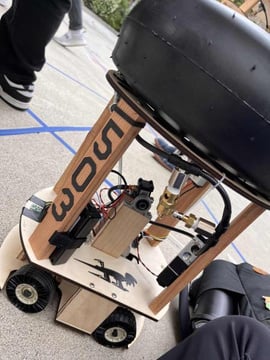

Attack on Droid Anthill - UCI

For the class project in MAE 106, we were to design and build an autonomous robot that follows a path. At the end of the class, my team was the only one to consistently hit the target every time. We won first place.

Every person on the team was assigned a specific role. My role was the electrical components. I soldered and calibrated the magnetometer and the solenoid, as well as set up the pneumatic system that powered the robot.

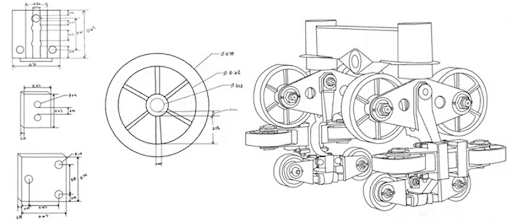

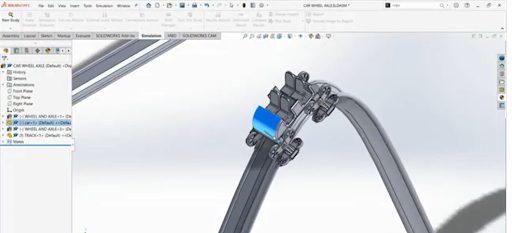

SolidWorks Rollercoaster - UCI

For my final project in MAE 52, the SolidWorks class, I designed a rollercoaster. I drew out the wheels first with dimensioning and fit the coaster car to the wheels. I tested the static load of the average weight of a rollercoaster car and people in the seats, as well as a Von Mises stress distribution. Then I created a spline for the track and using a reference point I created mates to allow the car to follow the track.

You can view my MAE 52 project here: https://youtu.be/s38XtfuVQKw

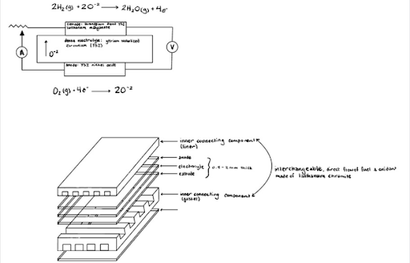

Gateway to Blue Skies - NASA

My team and I did extensive research over the course of an entire quarter. We analyzed the technology readiness levels of certain materials needed to produce an effective power density able to fly a plane from Phoenix to LA (2 hour flight). While not possible at the moment, with effective testing and continuation of our research, we determined that SOFCs and PEMFCs would achieve carbon neutrality goals despite manufacturing carbon footprints.

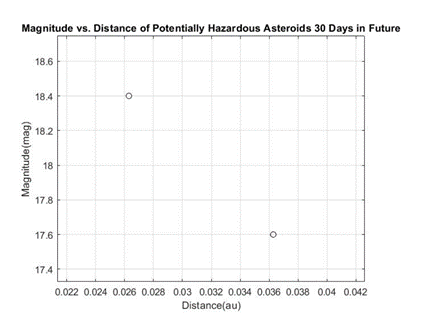

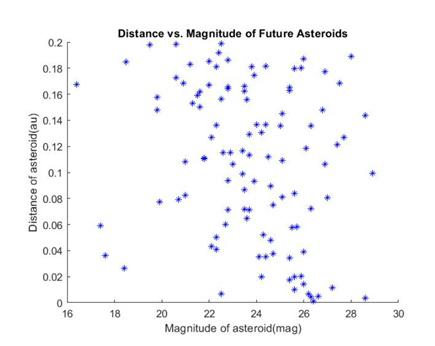

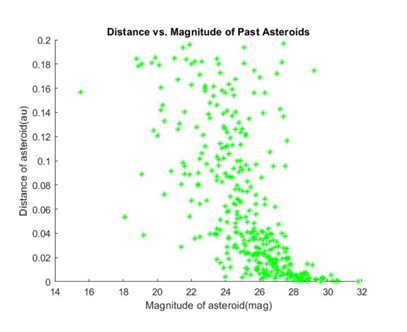

Potentially Hazardous Asteroids - UCI

We were given the creative freedom to choose what our project would be about from our interests. Team Inferno chose to analyze the magnitude and distance of potentially hazardous asteroids, a term NASA uses to describe asteroids that have potentially disastrous effects when too close to earth’s atmosphere.

In this project, while the focus was learning MATLAB functions, the research and effort put into the success of the project was more of a learning experience for engineering applications. We used a real-life problem to code a preemptive warning system to allow for more time to prepare for natural disasters from outside our atmosphere.

You can find my project here: https://docs.google.com/document/d/1HhnoldYU0gdm_oT5NRlUZpD67avT-INtDV9zvu9Bj6s/edit?usp=sharing

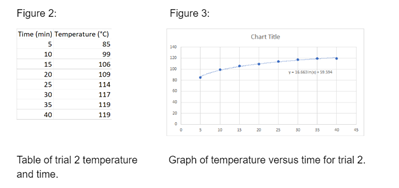

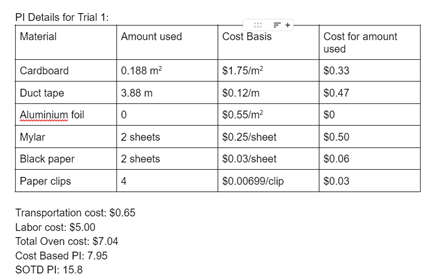

Solar Oven - UofA

I took a dual enrollment class in high school with the University of Arizona. With the problem of an unattainable price for necessary household appliances, we came up with the idea to utilize and test solar ovens with cheap materials to effectively cook a biscuit.

This was my first engineering challenge in which I had to research a problem, design a solution, build a prototype, and test it with quantitative data. Then I learned how to write a formal engineering final report as well as important budget documentation skills. I worked as a team with two other students to get the second highest temperature reached, and the only group to not burn the biscuit after two trials.

You can view my final report here: https://docs.google.com/document/d/1YwgqCUzaDRDkKlBHl4v5yLc-ATqWSnKyxA7j2o9IIUQ/edit?usp=sharing

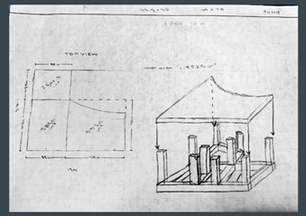

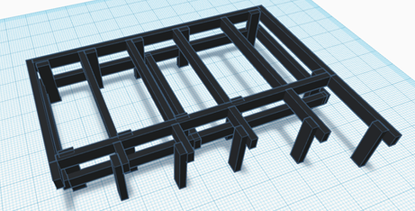

Stage Extension - UofA

At the end of my dual enrollment course at the University of Arizona, the students were tasked with finding a problem and using the engineering process to solve the problem. Our high school drama department was extremely underfunded, and couldn’t afford a stage extension for an actor in a wheelchair to fit on the stage. My team and I built a fully functioning stage extension that continues to hold over 1000 lbs.

In this project I learned fabrication skills using power saws and drills, as well as fundamental design concepts such as truss structures and the load-bearing capabilities of certain materials. After over four years, this stage extension continues to serve as a way for actors with accommodations to be able to perform.

You can view my final report here: https://docs.google.com/document/d/13hk6dt_UuHhl7gdB__TPi5Ui7tNCD_HDZsMSWDvWdcw/edit?usp=sharing

In Progress...

Ask me about...

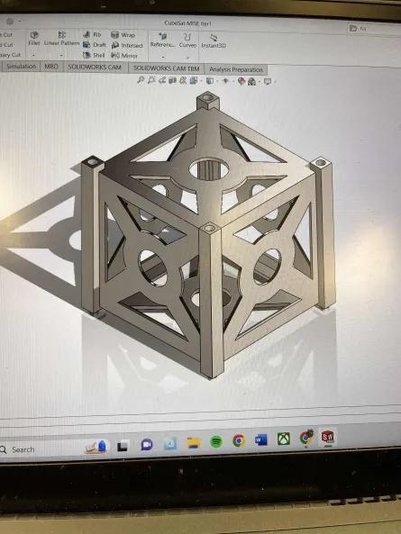

- MISE CubeSat Cooray and UCI CubeSat Team

- My Personal Projects